Kev piav qhia

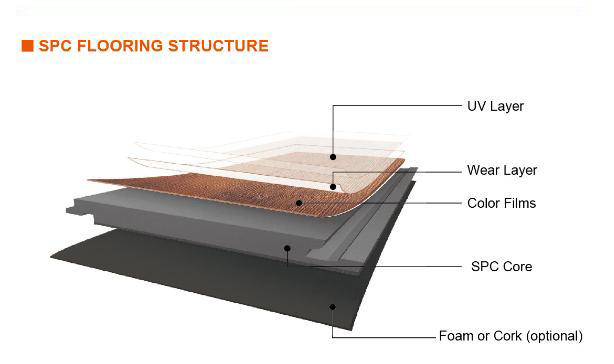

SPC flooring yog ib hom waterproof SPC yas plank flooring nrog nias system, nws yog formaldehyde dawb flooring, zoo dua dimensional stability, ib puag ncig tiv thaiv, yooj yim txij nkawm thiab yooj yim installation.SPC rigid core flooring yog haum rau tag nrho lub ntiaj teb no sab hauv tsev

L-SPC Technology: Sib zog 20% dua li ib txwm SPC, thauj khoom 20% ntau dua hauv ib lub thawv, qhov ntawd, txuag 20% tus nqi thauj khoom hiav txwv thiab cov nqi thauj khoom hauv av.Shortening lub sij hawm installation vim yooj yim tuav thiab yooj yim installation, yog li txo tus nqi zog.

On line EIR deg kev kho mob, txuag nqi zog tshaj li kub nias EIR tshuab, nws muaj nqi-zoo.Tag nrho cov qauv thiab xim yog ua tib zoo xaiv, thiab feem ntau cov qauv thiab xim yog tsim los ntawm peb lub tuam txhab.

Art parquet Kub nias EIR Technology, zoo meej EIR nto yog tsim los ntawm peb cov kws tshaj lij kub xovxwm tshuab.Simulated khoom ntoo parquet qauv coj ib qho zoo nkauj kos duab ntxim nyiam.

Herringbone ntawm SPC pem teb thiab laminate pem teb, Imitation tiag tiag ntoo pom cov nyhuv, nplua nuj installation txoj kev kom tau raws li cov neeg siv ntau yam kev xav tau.

Grout groove thev naus laus zis: qhov tseeb-saib grout zawj qhov system rau nyem-profiled WPC, SPC thiab L-SPC planks thiab vuas.Nrov ntau thiab tsawg: 610x610mm, 900x450mm, 610x305mm.

Daim ntawv thov

COV NTAUB NTAWV TSEEM CEEB:

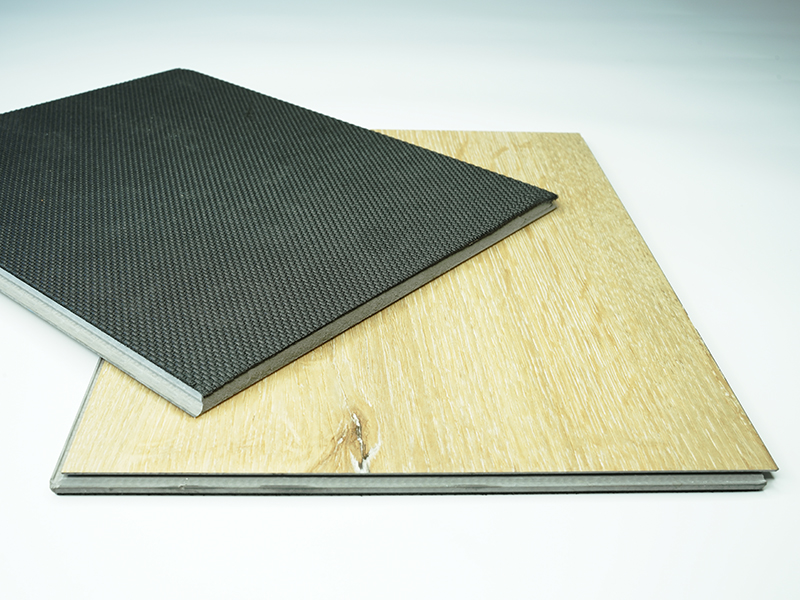

Thickness: 4mm, 4.5mm, 5mm, 6mm, 8mm.

Length thiab dav: 1218x228mm, 1218x180mm, 1218x148mm, 1545x228mm, 1545x180mm 1545x148mm, 610x610mm, 600x300mm, 9055x75mm, 905x75mm 0 x 600 mm

Hnav txheej: 0.2mm-0.5mm

INSTALLATION: Nyem LOCK

APPLICATION Scenario:

Kev siv kev kawm: tsev kawm ntawv, chaw cob qhia, thiab chaw zov me nyuam thiab lwm yam.

Kev kho mob system: tsev kho mob, kuaj thiab sanatorium thiab lwm yam.

Kev siv lag luam: Tsev so, tsev noj mov, khw, chaw ua haujlwm, thiab chav sib tham.

Kev siv hauv tsev: chav nyob, chav ua noj, thiab chav kawm thiab lwm yam.

LEEJ TWG

Siv cov ntaub ntawv nkauj xwb, dhau qhov kev sim thoob ntiaj teb, ua tiav cov txiaj ntsig ntawm tsis muaj formaldehyde, tsis muaj hlau hnyav, tsis muaj ntxhiab thiab tshuaj tua kab mob.

DURABLE:

Hnav kuj, khawb kuj, stain kuj

SAFETY:

Slip resistant, hluav taws resistant thiab kab pov thawj

CUSTOM - khoom:

Cov khoom loj, décor xim, cov qauv khoom, nto embossing, xim xim, ntug kho, gloss degree thiab kev ua haujlwm ntawm UV txheej tuaj yeem kho.

Cov ntaub ntawv technical

Hnub tim: 2022-01-26 Intertek Report No. 220110011SHF-001

Cov khoom xeem, txheej txheem thiab cov txiaj ntsig:

ASTM F3261-20 Txuj Specification rau Resilient Flooring hauv Modular Hom nrog Rigid Polymeric Core

Lub cev xav tau:

| Yam ntxwv | Cov kev cai xeem | Txoj Kev Xeem | Txiav txim |

| Residual indentation | Nruab nrab ≤ 0.18mm | ASTM F 1914-18 Cov Lus Qhia | Hla |

| Dimensional stability | Qhov chaw nyob, (avg, max) ≤0.25% Kev lag luam, (max) ≤0.2% | ASTM F2199-20 (70 ℃, 6 teev) | Hla |

| Curl | ≤0.080 hli | Hla | |

| Tiv thaiv kom sov | (avg, max) ΔE* ≤ 8 | ASTM F1514-19 Cov Lus Qhia | Hla |

Nco tseg:

1. Cov khoom kuaj selscted los ntawm tus neeg thov.

2. Cov ntsiab lus xeem kom ntxaws saib nplooj 5-7.

Page 4 ntawm 13

Cov khoom xeem, txheej txheem thiab cov txiaj ntsig:

Cov khoom kuaj: Residual indentation

Txoj Kev Xeem: ASTM F3261-20 ntu 8.1 thiab ASTM F1914-18

Conditioning: Conditioning cov qauv kuaj ntawm (23 ± 2) ° C thiab (50 ± 5)% txheeb ze av tsawg kawg 24h

Kev Xeem Xeem:

Indenter: Steel cylindrical ko taw

Indenter txoj kab uas hla: 6.35mm

Tag nrho qhov hnyav: 34 kg

Indentation lub sij hawm: 15 min

Lub sij hawm rov qab: 60 min

Kev Xeem Xeem:

| Residual Indentation | Cov txiaj ntsig (mm) |

| Qauv 1 | 0.01 ib |

| Qauv 2 | 0.01 ib |

| Qauv 3 | 0.00 Nws |

| Tus nqi nruab nrab | 0.01 ib |

| Max.tus nqi | 0.01 ib |

Hnub tim: 2022-01-26 Intertek Report No. 220110011SHF-001

Cov khoom xeem, txheej txheem thiab cov txiaj ntsig:

Cov khoom kuaj: Dimension stability thiab curling

Txoj Kev Xeem: ASTM F3261-20 ntu 8.3 thiab ASTM F2199-20

Kev kho mob:

Kub: 23 ° C

Tus txheeb ze humidity: 50%

Duration: 24 h

Ntsuas qhov pib ntev thiab curling

Kev Xeem Xeem:

Kub: 70 ° C

Duration: 6 h

Kev kho dua tshiab:

Kub: 23 ° C

Tus txheeb ze humidity: 50%

Duration: 24 h

Ntsuas qhov kawg ntev thiab curling

Kev Xeem Xeem:

| Cov qauv | Dimensional stability (%) Ntev kev taw qhia / Tshuab kev taw qhia Dav kev taw qhia / hla tshuab kev taw qhia | Curling (hauv) | |

| 1 | -0.01 Nws | 0.01 ib | 0.040 ib |

| 2 | 0.00 Nws | 0.01 ib | 0.025 ib |

| 3 | -0.01 Nws | 0.00 Nws | 0.030 Nws |

| Nruab nrab | -0.01 Nws | 0.01 ib | 0.032 ib |

| Max. | -0.01 Nws | 0.01 ib | 0.040 ib |

Cov khoom kuaj: Ua kom sov

Txoj Kev Xeem: ASTM F3261-20 ntu 8.5 thiab ASTM F1514-19

Conditioning: Conditioning cov qauv kuaj ntawm (23 ± 2) ° C thiab (50 ± 5)% txheeb ze av tsawg kawg 24h

Kev Xeem Xeem:

Kub: 70 ° C

Lub sij hawm xa tuaj: 7 hnub

Spectrophotometer: Raws li D65 tus qauv teeb pom kev zoo, 10 ° soj ntsuam

Kev Xeem Xeem:

| Cov qauv | ΔE* | Qhov nruab nrab ΔE * |

| 1 | 0.52 ib | 0.71 ib |

| 2 | 0.63 ib | |

| 3 | 0.98 ib |

Daim duab kuaj:

Tom qab nphav raug los sis ntsib

Vim Li Cas Xaiv Peb

Peb lub peev xwm:

- 3 lub tshuab profile

- 10 lub tshuab extrusion

- 20+ cov khoom siv kuaj

- Qhov nruab nrab muaj peev xwm ib hlis twg yog 150-200x20'containers.

Guarantee:

-15 xyoo rau kev nyob,

-10 xyoo rau kev lag luam

Daim ntawv pov thawj:

ISO9001, ISO14001, SGS, INTERTEK, CQC, CE, FLOOR SCORE